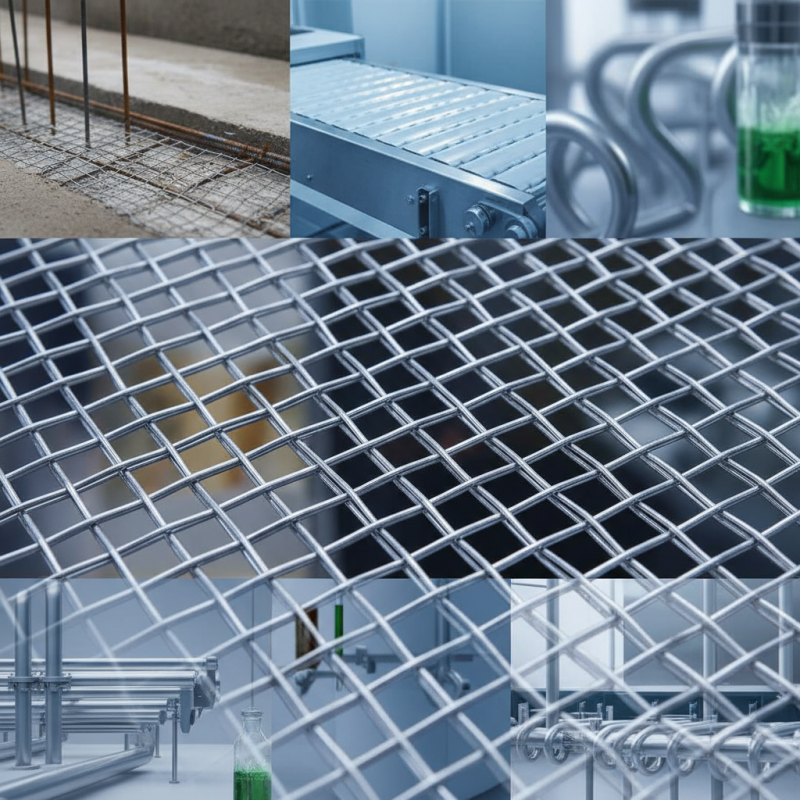

What is Stainless Steel Wire Mesh and Its Uses?

stainless steel wire mesh is versatile and durable. It consists of thin strands of stainless steel woven together. This material is used in various industries due to its unique properties.

In construction, stainless steel wire mesh reinforces concrete. It prevents cracks and enhances structural integrity. In the food industry, it serves as a filtration medium. Its non-corrosive nature is ideal for food safety. The chemical industry also benefits from stainless steel wire mesh. It resists corrosion from harsh chemicals, ensuring longevity.

Despite its advantages, stainless steel wire mesh may have downsides. The cost can be higher than other materials. Additionally, improper installation can lead to failures. Reflecting on these issues helps improve usage. Understanding stainless steel wire mesh is crucial for effective applications.

Definition of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material made from stainless steel strands woven together. Its durability makes it resistant to rust and corrosion. This unique property is essential in various applications. The mesh is created in different gauges and hole sizes, catering to specific needs.

In construction, stainless steel wire mesh is commonly used for reinforcement. It adds strength to concrete structures. In the food industry, it serves as a filter or screen. It maintains hygiene standards while allowing air and liquids to pass through. Moreover, it is utilized in architecture for aesthetic facades and safety barriers.

There are challenges when using stainless steel wire mesh. Cost can be higher than other materials. Designers may struggle to find the right size or type for particular projects. Additionally, installation might require skilled labor. Mistakes can lead to issues later on. Understanding the limitations and possibilities is crucial in selecting the right mesh for your needs.

Types of Stainless Steel Wire Mesh

Stainless steel wire mesh comes in various types, each designed for specific applications. Common types include woven mesh, welded mesh, and perforated sheets. Woven mesh is typically used in filtration systems and architectural projects. It is strong and allows for excellent airflow while preventing unwanted particles from passing through.

Welded mesh is another popular option. It provides enhanced strength and durability, making it ideal for construction and security applications. This type tends to be more rigid and is often used for fencing or as reinforcement in concrete. Perforated sheets feature holes punched through the material, offering unique design benefits in both commercial and residential settings.

Tip: When selecting stainless steel wire mesh, consider the wire diameter and mesh size. Thicker wire provides more strength, while smaller mesh sizes enhance filtration levels. Choose according to specific project needs.

Another point to ponder is the material's susceptibility to corrosion. While stainless steel is known for its resistance, not all grades perform equally under different environments. For instance, some may rust when exposed to harsh chemicals. Be thoughtful about your choice of material and its intended use.

Types of Stainless Steel Wire Mesh and Their Popular Uses

This chart represents the various types of stainless steel wire mesh and their common applications. As shown, architectural applications dominate the usage, followed by industrial and filtration purposes.

Manufacturing Process of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material widely used in various industries. Its manufacturing process starts with selecting high-quality stainless steel. This ensures durability and resistance to corrosion. Wire is drawn through a series of dies to achieve the desired diameter. Each step requires precision to maintain consistent quality.

After drawing, the wire is woven into mesh. Various patterns can be created, allowing for specific applications. Machines typically handle this weaving process, yet some artisans continue to weave by hand. While automated processes enhance efficiency, the human touch adds unique characteristics. Each mesh has its own story and imperfections.

The final step involves cutting the mesh to specified dimensions. This can lead to waste, as not every piece is perfect. Some may have defects or sizing issues. It's essential to test samples for strength and flexibility. Quality checks often highlight areas needing improvement. Ensuring each mesh meets standards can be challenging, but it's crucial for performance.

Common Applications of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material, widely used across many industries. It offers excellent corrosion resistance and durability, making it ideal for both indoor and outdoor applications. According to market research, the global wire mesh market is expected to grow annually by 5.2% from 2021 to 2026. This growth reflects increased demand in construction and manufacturing sectors.

One common use is in construction. Builders often utilize stainless steel wire mesh for reinforcement. This enhances the strength of concrete structures. It also prevents cracking over time. In agriculture, it plays a significant role. Farmers use this mesh for fencing and sifting soil. This application helps manage the land while keeping pests at bay.

In the filtration industry, stainless steel wire mesh is invaluable. It filters liquids and gases, providing a reliable solution for various processes. However, depending on the specific application, wire mesh can sometimes fail to meet expectations. Issues like incorrect gauge or weave might reduce effectiveness. Careful selection of materials and specifications can prevent these drawbacks.

Benefits of Using Stainless Steel Wire Mesh

Stainless steel wire mesh is known for its strength and durability. It’s widely used in construction, filtration, and various industrial applications. One key benefit is its resistance to corrosion, making it suitable for harsh environments. According to industry data, around 45% of stainless steel mesh is used in architectural applications. This serves to improve both safety and aesthetics.

Another significant benefit is the mesh’s excellent tensile strength. This feature ensures that the material can withstand heavy loads. A report by the Metal Construction Association states that stainless steel wire mesh can support weights nearly three times greater than plastics. Additionally, stainless steel is recyclable. Using it can lead to lower environmental impact.

However, it is essential to consider costs. Stainless steel wire mesh is more expensive than alternatives. This could be a barrier for some projects. Also, some professionals may overlook installation intricacies. Proper handling and installation are vital for achieving desired outcomes. Overall, there are impressive advantages, but awareness of potential drawbacks and application challenges is necessary.

Article Source:

CORPORATE HEADQUARTERS

North America

California

AGIC Energy North America LLC

13025 Danielson Street, Suite 105

Poway, CA 92064 – USA

Phone Number: +1 (858) 842 1513

Email: info@site_cc52bd27-560c-4f9d-bd66-63718fc42539

Sales: sales@site_cc52bd27-560c-4f9d-bd66-63718fc42539